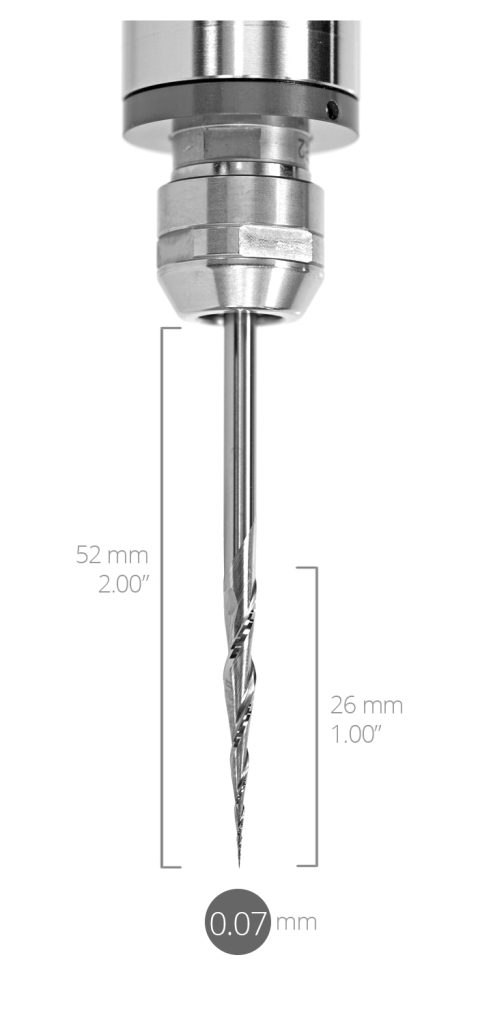

NS CNC, being a leader in the production of 5 axis CNC machines for jewelers, began the research and development of a milling bit even longer, up to 26 mm. The manufacturing of such bits should have a spherical shape and a diameter of 0.1 mm, in this case, the run out of the tip should be limited to 1 micron or less

Numerous tests and trials, the first versions of the cutter began to appear. Machine users were very pleased with the appearance of the first long cutters with such precise characteristics. This made it possible to produce much more complex wax models that could not be achieved with traditional short bits.

But, having made the first Mira Bits a few years ago, we did not stop at the success we achieved. Changing the geometry of the flutes, helix angle, and other parameters, we have achieved superior results. The bit that we now supply with the machine can mill the most complex models up to a full depth of 26 mm, without preliminary or rough milling, at full feed rate.