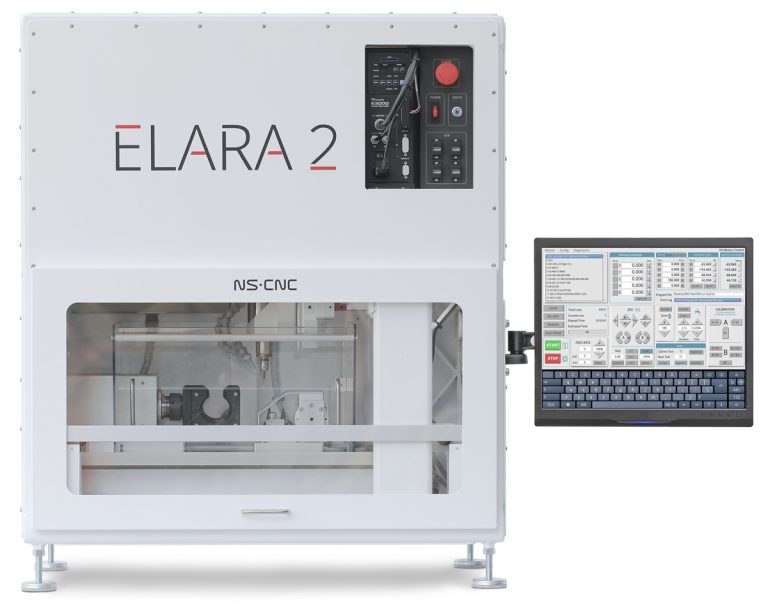

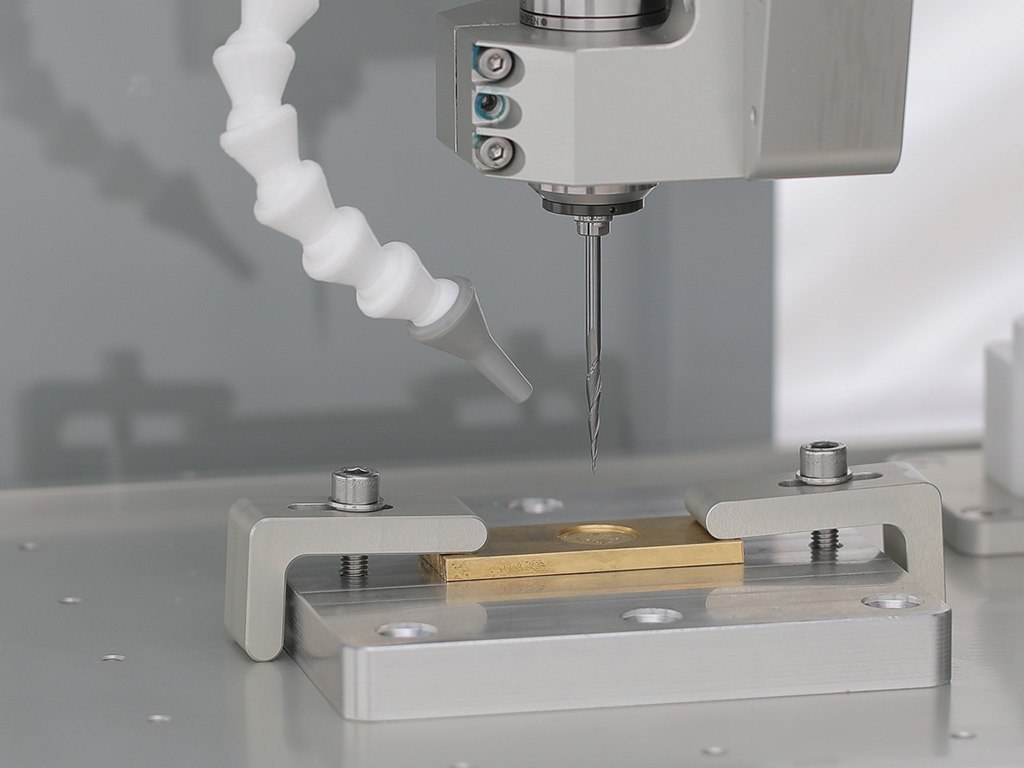

Despite its small size, the Elara Milling Machine has incredible strength and precision. Using it’s advanced system of servo motors, ball-screw railings and robust capacity the Elara can machine the smallest gears with meticulous accuracy while having the power to cut down entire stainless steel cases.

Combined with the Elara Lathe, the watchmaker has the tools necessary to create unique one-of-a-kind timepieces or restore high-end or hard-to-get parts. The Elara is trusted by some of the world’s greatest artisans to create incredible, unique timepieces – find out if the Elara is the right fit for you at nscnc.com

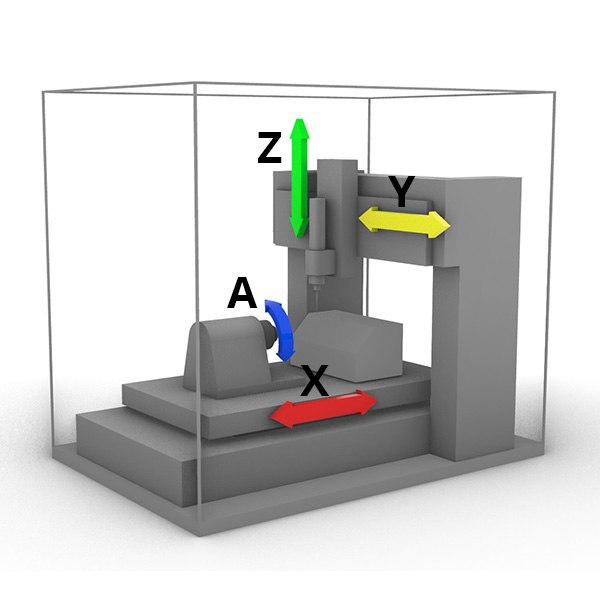

The machine is produced in two basic configurations: 3-axis and 4-axis. Each of them can be equipped with an Automatic Tool Changer (ATC). In addition, at the customer’s request, various workpiece holders, an additional spindle, laser, tailstock, etc. can be added to the machine.

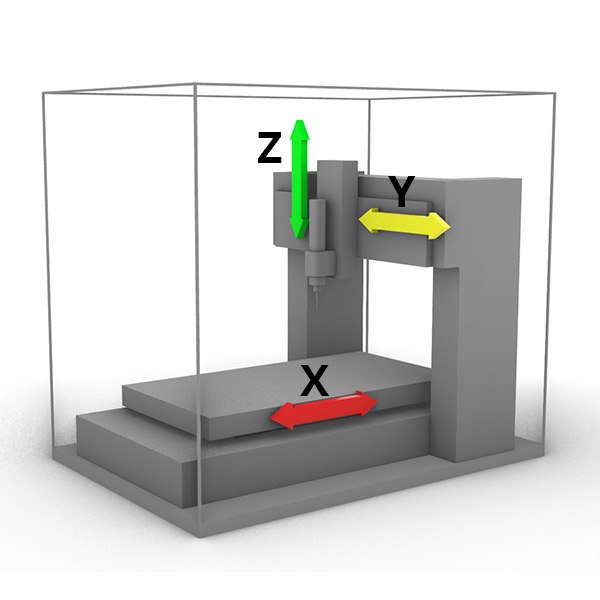

Traditional 3 axis CNC machine configuration. Simple and easy setup for milling flat parts. The spindle moves along 3 axis and the workpiece is mounted directly onto the X carriage. The direct clamping helps with stability and minimizes vibrations.

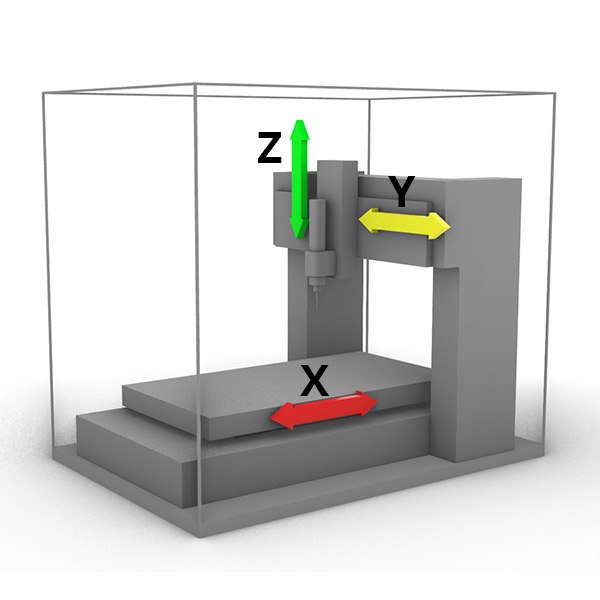

3-axis CNC milling machine with ATC and spindle that automatically changes the milling bit. This machine allows for fully automated milling bit change process during operation. ATC requires air supply.

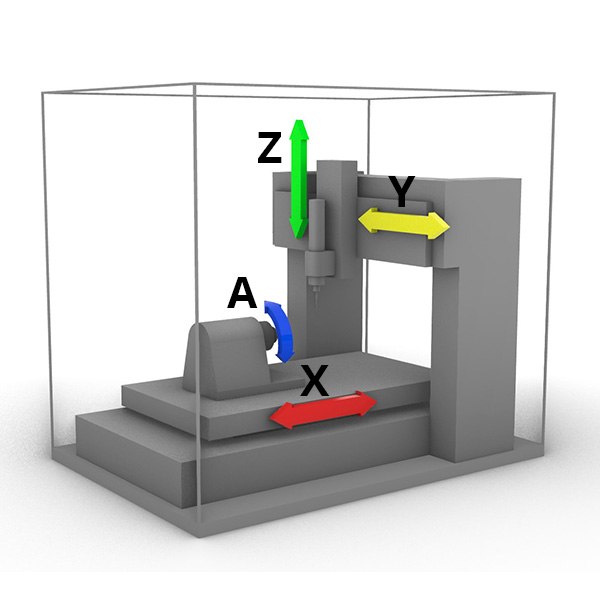

4-axis CNC machine in which the 4-axis A is a rotary head rotating around the X-axis. The machine can operate in the same way as a 3-axis machine. It’s very useful for those who mill various parts by combining three and four axis milling strategies.

4-axis machine with ATC is the most advanced configuration of the machine, giving the user enormous milling capabilities despite the higher price. But operating such a machine requires the operator to have extensive knowledge and experience in CNC.

The product images shown are for illustration purpose only. Actual product and specifications may vary due to product enhancement and continuous improvement

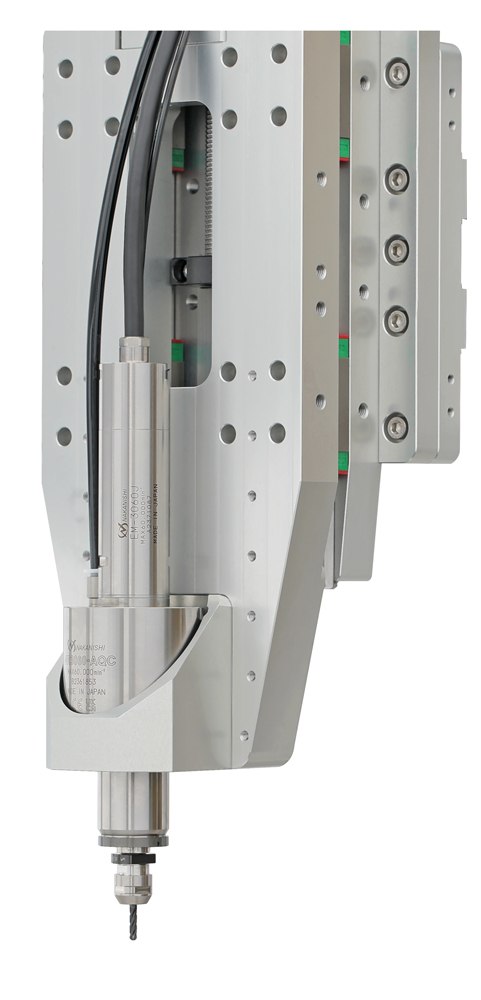

When ordering a machine, you have the opportunity to choose the spindle that best suits your needs and fits your budget. All NS CNC machines are equipped with spindles from the world-famous NSK Nakanishi corporation. Only four main spindles are shown here.

But we have the opportunity to order any of their other spindles, of which they have dozens of models. You can read more about NSK Nakanishi here https://en.nakanishi-spindle.com/.

Easy-to-use spindle for milling soft materials. Milling bits are changed using a manual Quick Lever Changer. Not recommended for metal milling. Unlike other spindles, it has a very limited number of collet sizes. This is not so important for standard milling bits. But it will complicate the use of drill bits of different diameters.

The most popular spindle for metal milling where automatic tool change is not required. The best ratio of price, power and accuracy. It is known for its very high reliability and durability. It can work for a long time in very dirty environments, such as when milling soft stones.

The most popular spindle with ATC (Automatic Tool Changer) or AQC (Air Quick Change). Which is done using a pneumatic clamp inside. Accordingly, air is required for the spindle to operate. Significantly more expensive than spindles without automatic change.

This is the most powerful spindle of the E3000 – E4000 series witrh ACT. It is used for milling stainless steel, titanium and other hard materials. Three to four times more powerful than all other NSК spindles. But it is also many times more expensive than others.

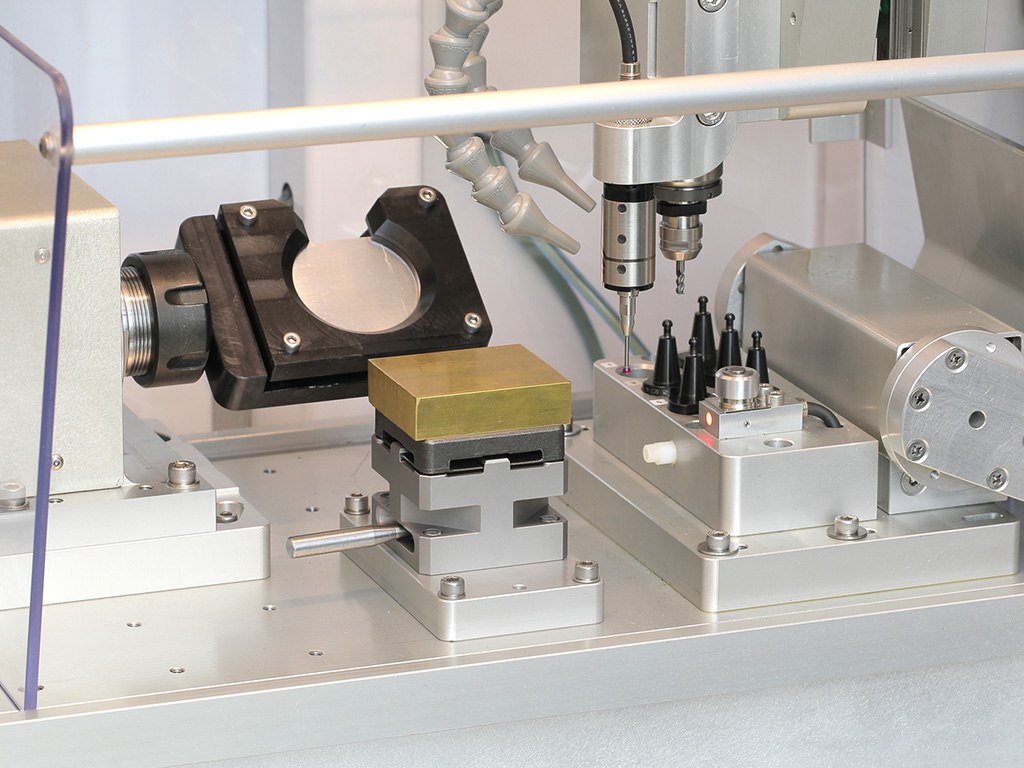

If you want to mill complex parts using different milling bits, then you can order an additional Auto Tool Changer. Usually, 6-bit pots are enough. But if you need more, then we are ready to install an enlarged changer for 12 bits. The Changer requires a spindle with an auto clamp. We’ll install such a spindle on the machine for you without any problem.

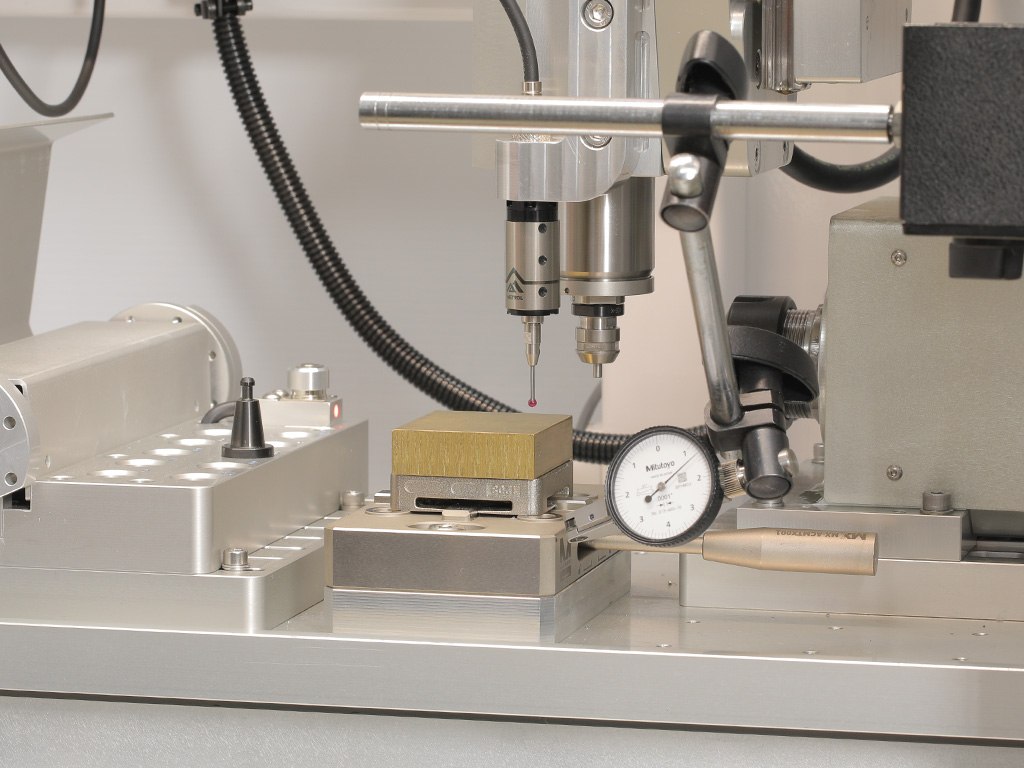

The machine features a universal workpiece clamping system, enabling users to secure workpieces made from various materials and in different shapes.

All holders are mounted on the main X-axis table, which is equipped with multiple M5 threaded holes spaced 25 mm apart.

This design allows for flexible mounting of various components on the table, much like a Lego system. Unused holes are covered with set screws to prevent dirt and chips from entering.

If your milling strategy requires positioning of different workpieces with perfect repeatability, we offer you workpiece holders from Maxx Tooling, the world leader in performance holding systems. They are designed for maximum efficiency, reliability, and the highest quality.

We are ready to help you choose the right configuration, as well as provide you with an adapter, with which you can install the holder to the machine table or rotary head.

Elara Milling Machine is widely used in the watchmaking industry for the manufacturing of custom timepieces and machining of movement parts for repairing and restoring watches.

The heavy-duty base and carriages allow the Elara to machine not only soft metals such as brass and gold but harder materials like titanium and stainless steel.

The Elara can perform both, traditional 3-axis milling with a fixed work-piece directly attached to the X-table and the more complex 4-axis auto-flip with an additional rotary head.

In addition to the milling machine, NSCNC also produces a turning variation of the Elara. This mini-lathe can be be equipped with various cutters and watchmaking collets which allow it to process a work-piece from different angles.

This turning variation of the Elara combines the traditional watchmaker’s lathe with the latest CNC systems to allow the operator to push the limits of precision and capability.

Enhance your setup with a dedicated machine stand designed for both mobility and stability. The stand comes equipped with heavy-duty casters and integrated leveling mounts.

This dual system lets you easily roll the machine around your workshop and, once positioned, raise it off the casters using the mounts. Because the mounts are positioned slightly outward from the machine’s footprint, they deliver exceptional stability and significantly reduce vibration during operation.

The stand also includes a lower shelf sized for a coolant tank and a convenient pull-out tray. The tray provides accessible space for tools, milling bits, or peripherals such as a keyboard and mouse, helping you keep your workspace organized and efficient.