Our first five-axis NS CNC machine was created in 2009. There was, of course, the question of how to name it. Some days we were tormented by the challenge of creating a name. We had an excellent example of the name of our competitor’s machine, “REVO”. This was the first part of the word “Revolution”.

Yes, many years ago, this machine made a revolution in the jewelry business. But what are we getting out of our new machine? Would we all want a new revolution? No, we weren’t going to make more revolutions or give the industry a shock. We just wanted to produce a pleasant and convenient machine for jewelers.

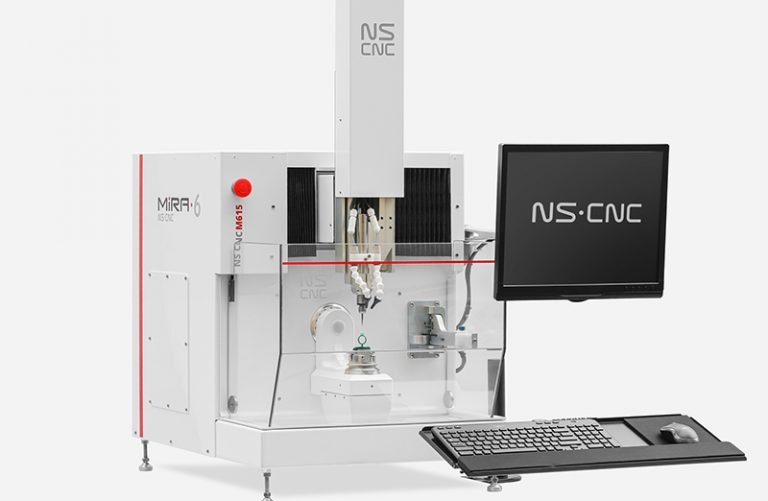

To find the right name, we first had to think about what kind of machine we wanted our customers to have. Should it be revolutionary, high-tech, suicidal, one-of-a-kind or irresistible? Or maybe just a little magic or a miracle? Miracle? Mira-cle! Bingo! Our machine will be called MIRA!

Connoisseurs immediately pointed out that Mira is a very famous star in the constellation of Cetus. This is also a great reason for the name “MIRA”! But, let the user of the machine decide for himself whether he is a star or a miracle machine.

After several years of producing and selling hundreds of machines, we began to learn that our customers sometimes change the name of the machine themselves a little. The machine became a jeweler’s friend, a family member, or a business partner, so they gave it a nickname.

The first such dialogue was with one client from Australia:

– “Miranda has worked the last two weeks without stopping at all…”

– “We are very pleased, but who is Miranda?”

– “This is your Mira! But in my family, her name is Miranda.”

– “Ok!”

Then we learned that the machine was given some of the most unusual names in different cities and countries, such as Myra, Mirochka, Miroslava, Maria, and Meir. We are not opposed to such variations of the name. To us, the main thing is that users love their MIRA !

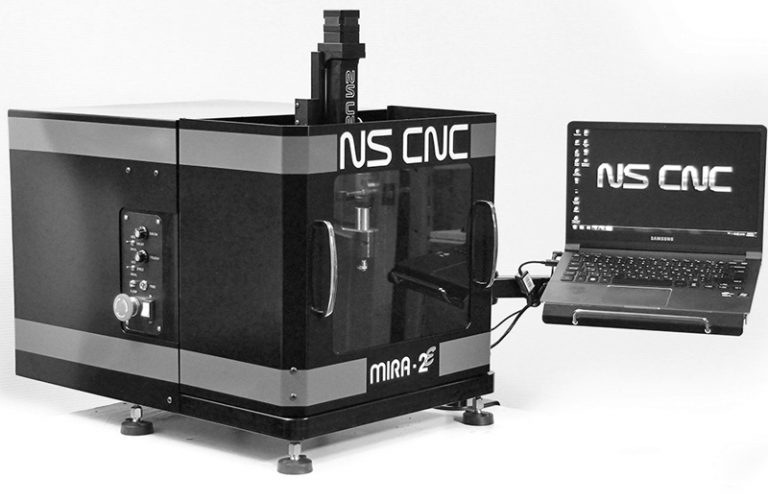

In the first years of production, there was only one thing we had to do: change the color of the machine. Customers complained. “If your machine is a star, then why is it black?” So, at first, we changed it to light gray, and then to pure white, as it has been and is to this day.